An Engineered Approach to Testing

Through hundreds of hours of flight testing our airframe designs, we have established that there is a direct correlation between the airframe and drive system and one affects the other with consequences to the desired aerodynamic performance. We designed our power plants with the airframe that promotes efficient cooling. The idea behind the design was to allow the power plant and airframe to work in harmony in order to achieve optimum performance, that could never be easily achieved with a mix and match approach. Every step of the design from the airframe, motor, speed controller through to the matching power packs have been done in a very careful and measured fashion with the sole propose to achieve the maximum aerodynamic performance without compromising flight time. We call the result iPAs, PA Integrated Performance Airframe-Drive System, allowing any modeler to get it right the first time in the simplest and shortest way; the completely hassle free buy, fix, fly and forget method.

Through hundreds of hours of flight testing our airframe designs, we have established that there is a direct correlation between the airframe and drive system and one affects the other with consequences to the desired aerodynamic performance. We designed our power plants with the airframe that promotes efficient cooling. The idea behind the design was to allow the power plant and airframe to work in harmony in order to achieve optimum performance, that could never be easily achieved with a mix and match approach. Every step of the design from the airframe, motor, speed controller through to the matching power packs have been done in a very careful and measured fashion with the sole propose to achieve the maximum aerodynamic performance without compromising flight time. We call the result iPAs, PA Integrated Performance Airframe-Drive System, allowing any modeler to get it right the first time in the simplest and shortest way; the completely hassle free buy, fix, fly and forget method.

What iPAs means to you, the modeler? iPAs provides a pre-matched, optimum gear setup derived from hundreds of hours of flight testing that would make your PA model perform as advertised out of the box. This also means you will no longer need to try and figure out by experiments what gear best matches the airframe and the desired flight performance.

While this may sound easy, testing is actually a very complex task that should be done carefully. Any variations with the type of ESC set up, ESC brand, type of battery, charging of the battery pack (can even vary between same brand and type of pack), type of chargers, climate (environment temperature) and testing gear will derive different results. Even the duration of the bench run will change the reads due to the battery voltage drop caused by the internal resistance of the battery as well as the age of the battery. All those factors can create A LOT of read variations.

We conducted multiple tests (both static and dynamic tests) on each of our motors in different climates/temperature, using different testing equipment, changed ESC and batteries to determine the real performance of the motor. We also had the model flown by multiple test pilots to obtain different individual flying styles.

We conducted multiple tests (both static and dynamic tests) on each of our motors in different climates/temperature, using different testing equipment, changed ESC and batteries to determine the real performance of the motor. We also had the model flown by multiple test pilots to obtain different individual flying styles.

We believe that drive system testing should not be purely based on bench testing, because those are clinical test done in controlled environments that are completely different from actual flight conditions. Interactions of external environmental factors such as cooling, propeller loading, G-Force etc. can not be accurately simulated on the bench. The real performance data comes from actual flights because this is where it counts the most.

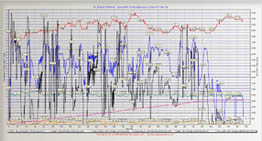

Therefore, we have taken the approach to conduct actual live (dynamic) test to acquire our data, i.e. flying the actual aircraft and performing actual 3D maneuvers, like any other experienced modeler would. We do not simply fly straight and level circuits and performing simple aerobatic maneuvers during our flight test but we actually fly our aircraft to the maximum limits of their aerodynamic performance envelope.

In 3D flights, thrust and power usually require the immediate power for few seconds to get out of a maneuver. We have based our static tests on this datum. We used 4 different brands of testing gear to verify the results and accuracy of reads. Test results may vary depend on your set up of your ESC, climate, altitude, duration of run etc.

Our data sheets contain the results of both static and dynamic tests as well as the graphs and their analysis. We tried to make them as clear as possible for any user to read.